Best Brake Pads For Drilled Slotted Rotors

- Best Brake Pads For Drilled Slotted Rotors 2019

- Slotted Brake Rotor Noise

- What Type Of Brake Pads Are Best For Slotted Rotors

- Slotted Rotors And Pad Kits

Break-In is critical for optimal performance

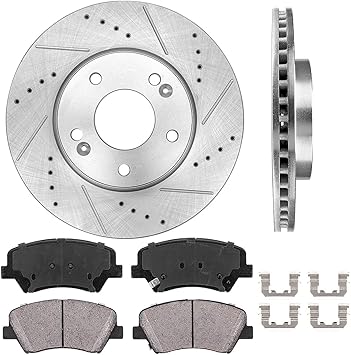

Drilled and Slotted Rotors are some of the the best Brake Rotors in the industry. SP Drilled and Slotted Rotors stand above the rest, with no sharp edges on the brake rotor surface, there is little to no risk of cracking or heat checking. Drilled and Slotted Rotors provide the best cooling to the braking surface, extending the life of both the brake rotors and the brake pads. The premium semi metallic brake Pads will give you a higher heat and friction level with the lowest dust possible. The Dimpled drilled and slotted brake rotors included in the kit are sold in pairs. The rotors come zinc coated in either black or silver to help prevent rusting and give you a performance race look. Welcome to Brakeworld. We are the nation's premier supplier for brake pads, brake rotors, and calipers. Whether you are looking for original equipment style brake parts, value line brake components for the price sensitive budget, or you have come to us for our specialty performance brakes you have found the right source. Best of the Best Power Stop Front Z23 Evolution Brake Kit Check Price Premium Option Power Stop delivers a top-notch product with this brake rotor kit. Has two front rotors and front brake pads made of ceramic to reduce noise fade.

The break-in procedure is critical to brake performance. The reason for a proper break-in is to establish an even layer of friction material deposited on the rotors from the brake pads. It is very important that this initial layer of friction material is evenly distributed.

Break in your PowerStop Brakes as follows:

Best Brake Pads For Drilled Slotted Rotors 2019

Slotted Brake Rotor Noise

What Type Of Brake Pads Are Best For Slotted Rotors

Slotted Rotors And Pad Kits

- 1

Complete 5 moderate to aggressive stops from 40 mph down to 10 mph in rapid succession without letting the brakes cool and do not come to a complete stop. If you're forced to stop, complete the stop and either shift the vehicle into park or give room in front so you can allow the vehicle to roll slightly while waiting for the track light. The rotors will be very hot and holding down the brake pedal will force the brake pad to contact the rotor and possibly create an imprint on the rotor. This imprint may contribute to the creation of brake judder.

Continue the break in by completing 5 moderate stops from 35 mph to 5 mph in rapid succession without letting the brakes cool. You should expect to smell some resin as the brakes get hot. After this is complete, continue to drive the vehicle for as long as possible without heating the brakes excessively and without coming to a complete stop (Try for about 5 minutes at moderate speed). This is the cooling stage.

Once this is completed and the brakes have cooled to standard operating temperature, you may use the brakes normally. Never cool your brakes with water, as this can damage them.